Introduction: The Silent Differences That Move Heavy Things

Here’s a clear frame: material flow is a chain of small, precise moves that add up to trust. A lifting robot waits under a stacked pallet at shift change while the air is cool and the aisles hum low. In that calm, systems like the lifting mechanism robot prove their worth by how they align, sense, and lift. Some sites report 6–10% of time lost to micro-stops or misalignments, often hidden in the day’s noise. With LiDAR watching edges and torque control smoothing motion, the line between smooth lift and rough jolt is thinner than it looks (and fragile under rush).

So the question is simple: what subtle contrasts separate a steady, safe lift from a stop-start shift that frays morale? When payload capacity changes, when stretch wrap glints back at sensors, when pallets swell from humidity—do we still flow? Let’s track the small mechanics and the quiet data. Then we’ll see how choices stack into outcomes—funny how that works, right? Next, we’ll unpack where older methods stumble and why that matters.

Where Traditional Approaches Fall Short

What’s the real snag?

Direct answer: legacy lifts miss context. Fixed-height tables and simple AGVs assume perfect pallets. Floors are not perfect. Pallets warp. Labels peel. Without force feedback or robust kinematics, a lift meets a tilted deck and either scrapes, stalls, or trips a safety PLC. Look, it’s simpler than you think: small misalignments multiply. A few millimeters at entry become centimeters of error at full rise. Add battery sag and power converters throttling at peak draw, and cycle time drifts. Operators babysit. Throughput sinks.

Another flaw hides in sensing. Single-plane scanners leave blind spots near forks. Glossy wrap causes false positives. Inertial sensors smooth motion but can mask jerk at low speed. Without edge computing nodes to fuse LiDAR and vision, the robot reacts late. It over-corrects, then pauses. Telemetry stays shallow, so no one sees the pattern. Maintenance swaps a servo drive instead of fixing the root misalignment. Downtime looks “random.” It isn’t. It is design that never met real pallets on a real Tuesday.

Comparative Insight: Principles That Change the Lift

What’s Next

Now compare a context-aware stack: vision-plus-LiDAR fusion, closed-loop torque control, and dynamic fork alignment tied to real-time pallet geometry. The lifting mechanism robot reads edge profiles, estimates center of mass, and trims approach speed before contact. Edge computing nodes handle the fast math near the actuator, so corrections land within milliseconds. Kinematics adjust for deck height drift, and a safety PLC supervises without choking motion. Result: fewer re-tries, cleaner entries, less wear on the gearbox ratio— and yes, it matters.

Energy and health also flip in this model. Smart power converters smooth peaks on the DC bus. The system logs per-lift energy, fork deflection, and heat at the H-bridge. That telemetry feeds a light predictive model; it flags a sticking roller before it becomes a stall. Compare it to legacy kits that only count cycles. One preserves uptime. The other counts problems. In field terms, you feel it as steadier cadence, shorter clears after a nudge, and safer stops with measured decel. This is not flash. It is steady craft meeting busy floors.

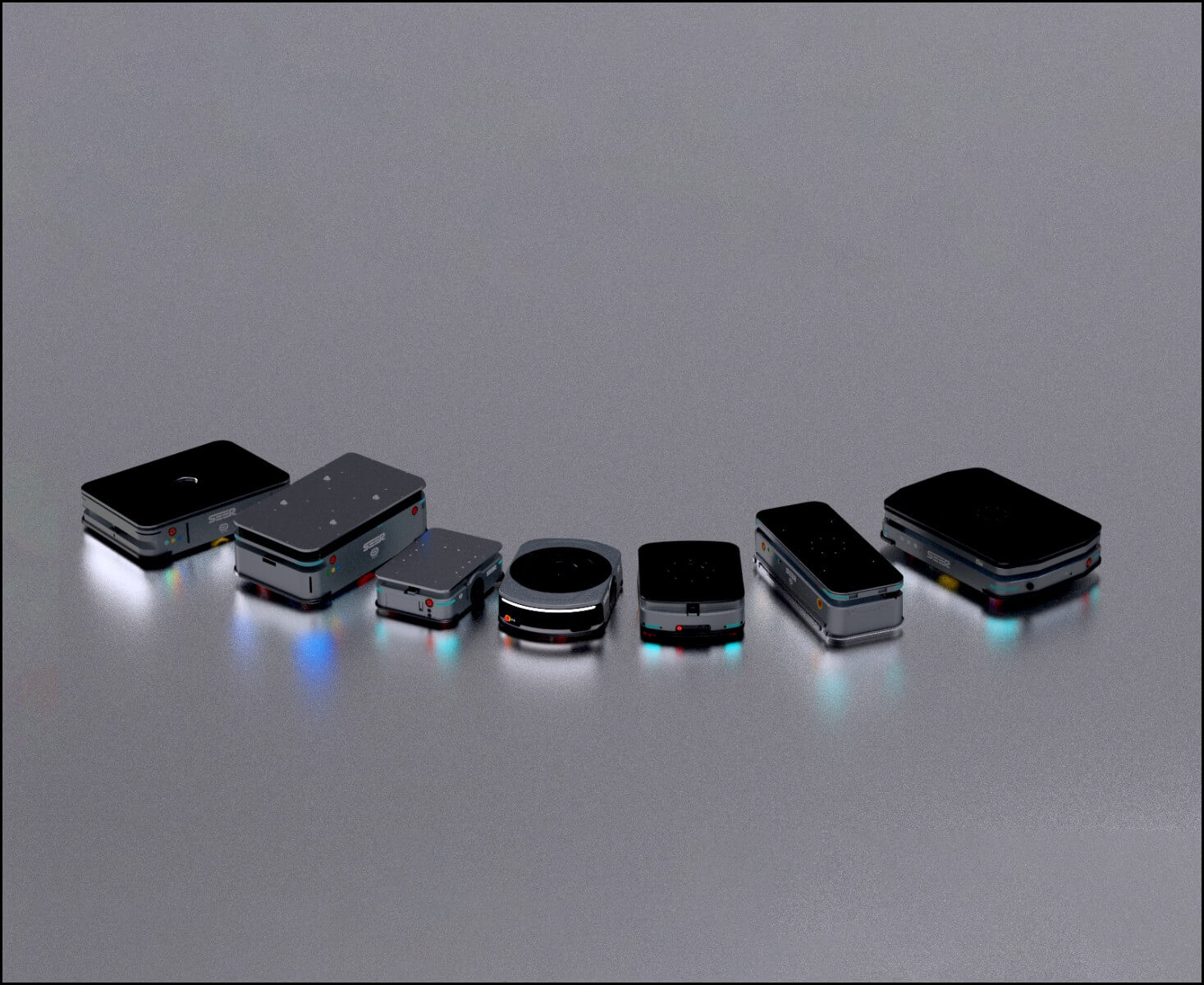

If you’re weighing options, focus on three checks. First, alignment fidelity under load: how many millimeters of error at 80% payload, measured at contact and at full lift. Second, resilience to messy pallets: success rate across warped decks, mixed skids, and reflective wrap—validated by logs, not demos. Third, response latency: from sensed misalignment to corrected motion, in milliseconds, including the control loop and actuator rise time. Those three metrics reveal the real difference between sleek slides and stop-start days. Keep them front and center, and your flow will tell you when you got it right. For continued insight into practical autonomy and safe lifts, see SEER Robotics.